factory price complete sugar beet pulp wood pellet making line

Brief

introduction

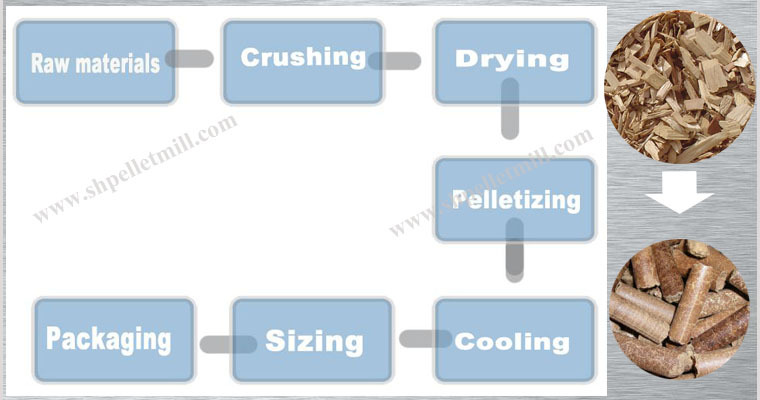

sugar beet pulp wood pellet line

is a complete pellet production line from raw material crushing to final wood pellets packaging. This plant is consisted of ring die pellet mill, screw conveyor, crusher, silo, Cooler, grading sieve machine, packing machine and control cabinet, etc.

sugar beet pulp wood pellet line

is a complete pellet production line from raw material crushing to final wood pellets packaging. This plant is consisted of ring die pellet mill, screw conveyor, crusher, silo, Cooler, grading sieve machine, packing machine and control cabinet, etc.

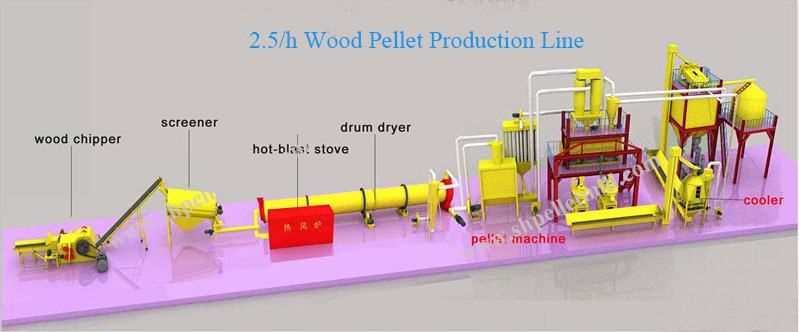

Complete

wood pellet production line is the complete one to make pellet from any type of

agro-forestry wastes with output 1ton/1hour; 2ton/1hour; 3ton/1hour; 4ton/1hour;

6ton/1hour; 8ton/1hour; 10ton/1hour.

Features of sugar beet pulp wood pellet line

compact structure, small occupation, low consumption and high efficiency.

Raw materials:

Suitable raw materials: Wood waste(a variety of spices of trees, lumber, timber, shrubs, sawdust, saw shavings, twigs and branches). Sawdust, groundnut shell, sugarcane biogases, caster shells/stalk, coffee husk saw dust, paddy straw, sunflower stalk, cotton stalk, tobacco waste, mustard stalk, jute waste, bamboo dust, tea waste, wheat straw, palm husk, soybeans husk, leaves, grass, coir pitch barks/straws, rice husks, forestry wastes, wood chips and other kind of agro wastes(rice husks, corn cobs, peanut shells, sunflower seed shells, coconut shuck, coffee grounds, straw stalks, cotton stalks, palm empty fruit bunches).

Features of sugar beet pulp wood pellet line

compact structure, small occupation, low consumption and high efficiency.

Raw materials:

Suitable raw materials: Wood waste(a variety of spices of trees, lumber, timber, shrubs, sawdust, saw shavings, twigs and branches). Sawdust, groundnut shell, sugarcane biogases, caster shells/stalk, coffee husk saw dust, paddy straw, sunflower stalk, cotton stalk, tobacco waste, mustard stalk, jute waste, bamboo dust, tea waste, wheat straw, palm husk, soybeans husk, leaves, grass, coir pitch barks/straws, rice husks, forestry wastes, wood chips and other kind of agro wastes(rice husks, corn cobs, peanut shells, sunflower seed shells, coconut shuck, coffee grounds, straw stalks, cotton stalks, palm empty fruit bunches).

Finished

pellets

Machines of sugar beet pulp wood pellet line

1. Raw materials pretreating section

Drum Wood Chipper (chip the raw wood into small pieces);

If the raw materials are grass or corn stalk, we need to use chaff cutter.

2.

Drying section

Dryer (reduce the raw material’s moisture to a suitable level for pelletizing);

The best moisture content to pelletizing is about 14-16%. raw material shall be pretreated well to achieve regulated moisture content and size. Generally, moisture content of material ought to be remaining around 13%-15%.

Dryer (reduce the raw material’s moisture to a suitable level for pelletizing);

The best moisture content to pelletizing is about 14-16%. raw material shall be pretreated well to achieve regulated moisture content and size. Generally, moisture content of material ought to be remaining around 13%-15%.

3.

Crushing section

Hammer Mill (grind the small pieces of wood into nearly powdery form for easy pelletizing);

Depending on the different input material, we fit out the suitable Crushing machines. If the raw material is the Straw Baler, we developed the series Baler Crusher adopting the foreign advanced technology. If the raw material is big logs with diameter less 300mm or big timber cutter, our BX-Series Chipping and Crushing Machine is your best choices; while SFSP-series Hammer Mill is widely used to crush each kind of straw, wood chip, tree branch, bark and leftover bits from agricultural wastes. The best moisture content in the Crushing Process is less 20%, and the thickness of the wood chip is less 5mm.

Hammer Mill (grind the small pieces of wood into nearly powdery form for easy pelletizing);

Depending on the different input material, we fit out the suitable Crushing machines. If the raw material is the Straw Baler, we developed the series Baler Crusher adopting the foreign advanced technology. If the raw material is big logs with diameter less 300mm or big timber cutter, our BX-Series Chipping and Crushing Machine is your best choices; while SFSP-series Hammer Mill is widely used to crush each kind of straw, wood chip, tree branch, bark and leftover bits from agricultural wastes. The best moisture content in the Crushing Process is less 20%, and the thickness of the wood chip is less 5mm.

4.Pellet

making section

Wood pellet machine takes biomass waste as raw material to make pellet fuel which is a kind of renewable energy replacing fossil fuel. Pelletizing is the process of making waste materials into solid fuel. The objects are used for burning purposes. Wood pellet machine is used to process raw materials into wood pellets. It is the corn component of the whole line, which can decide the capacity of the whole wood pellet line.

Wood pellet machine takes biomass waste as raw material to make pellet fuel which is a kind of renewable energy replacing fossil fuel. Pelletizing is the process of making waste materials into solid fuel. The objects are used for burning purposes. Wood pellet machine is used to process raw materials into wood pellets. It is the corn component of the whole line, which can decide the capacity of the whole wood pellet line.

5. Cooling section

Cooler (cool down the output pellets to avoid accumulation of heat that may destroy pellets);

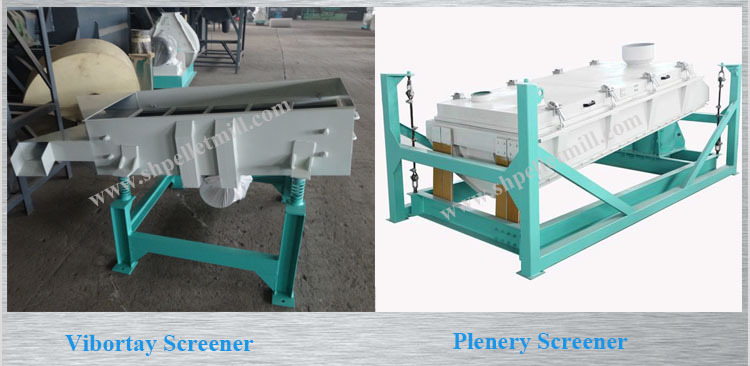

6.

Screening section

Sieving (remove the dusts and crushed pellets);

Sieving (remove the dusts and crushed pellets);

7.

Packaging section

Packing (pack the pellets into bags of required sizes);

Packing (pack the pellets into bags of required sizes);

8.Electric

control cabinet

Wood

pellet production line picture

Vertical

ring die straw wood pellet line

flat die

wood pellet line

flat die

wood pellet line

Company

Introduction

About Us

Shandong Double Crane Machinery Manufacture Co., Ltd. was established in 2009 and is located in Le-ling city, Shandong Province. We are dedicated to the development and production of feed equipment, biomass energy equipment and organic fertilizer equipment. Our company employs 150 skillful personnel. Therefore, we can easily meet your requirements. Thanks to our powerful distribution network, our products are popular with customers in many countries. With rapid development, we have passed CE, SGS and ISO9001 certifications and won many honorary titles. To learn more about what we can do for you, contact us anytime. We look forward to establishing a good and long-term business relationship with you.

About Us

Shandong Double Crane Machinery Manufacture Co., Ltd. was established in 2009 and is located in Le-ling city, Shandong Province. We are dedicated to the development and production of feed equipment, biomass energy equipment and organic fertilizer equipment. Our company employs 150 skillful personnel. Therefore, we can easily meet your requirements. Thanks to our powerful distribution network, our products are popular with customers in many countries. With rapid development, we have passed CE, SGS and ISO9001 certifications and won many honorary titles. To learn more about what we can do for you, contact us anytime. We look forward to establishing a good and long-term business relationship with you.

Our Team

If you are interested in our wood pellet machine, Please let us know the following basic information for making project:

A. What capacity would your prefer?

-----The capacity for ring die pellet mill model LS series is 0.1-10T/H.

B. What is your raw material and what is the size of your raw materials?

-----According to different raw material (such as hard wood, soft wood, straw, rice husk), capacity is different.

C. What's your requirement on the size of final pellets?

-----Best size for pressing high quality pellets is 4-12mm. Different sizes can be customized according to customer requirements

D. What is the moisture content of your raw material?

-----Better to be 10-15%. If the water content is too high, we need to use dryer in the production process.

E. What's your country industrial electricity voltage?

-----General 380V,50Hz,3Phase,if not match, tell us we can modify motor.

FAQ:

1. Q: Are you a trading company or a manufacturer?

A: We are a manufacturer, which has almost 10 years of experience in this industry and be able to offer you the best price.

2. Q: How can I get to your company?

A: You can get a flight to Jinan Airport. We are just about 1hour away from Jinan Airport.

3. Q: How long is your warranty period?

A: One Year (Calculated from the equipment arrives the customer’s side.).

4. Q: Will you send engineers to install the plant?

A: yes, but at an extra cost payable by the customer. Or you can get local contractors to do the commissioning and we send one supervising engineer.

5. Q: Have you sold your products to Europe?

A: Yes, We have designed and installed more than 1000 turnkey pellet lines. Many of our customers are from Europe, including Latvia, France, Greece, Romania, Lithuania, etc.

1. Q: Are you a trading company or a manufacturer?

A: We are a manufacturer, which has almost 10 years of experience in this industry and be able to offer you the best price.

2. Q: How can I get to your company?

A: You can get a flight to Jinan Airport. We are just about 1hour away from Jinan Airport.

3. Q: How long is your warranty period?

A: One Year (Calculated from the equipment arrives the customer’s side.).

4. Q: Will you send engineers to install the plant?

A: yes, but at an extra cost payable by the customer. Or you can get local contractors to do the commissioning and we send one supervising engineer.

5. Q: Have you sold your products to Europe?

A: Yes, We have designed and installed more than 1000 turnkey pellet lines. Many of our customers are from Europe, including Latvia, France, Greece, Romania, Lithuania, etc.

After-sale

Service:

1. Technical support online service provided.

2. Technical files service provided,

3. On-site training service provided.

4. Spare parts replacement and repair service provided.

Contact Us:

Please feel free to contact us for any question, we will reply within 24h.

1. Technical support online service provided.

2. Technical files service provided,

3. On-site training service provided.

4. Spare parts replacement and repair service provided.

Contact Us:

Please feel free to contact us for any question, we will reply within 24h.

评论

发表评论